Position:Home > News > Industry News > A Complete Buyer’s Guide to Choosing the Right AI Hydraulic Control Valve for Your Application

A Complete Buyer’s Guide to Choosing the Right AI Hydraulic Control Valve for Your Application

In modern industrial automation, AI hydraulic control valves have become essential components for achieving precision, efficiency, and reliability in fluid power systems. Selecting the right valve for your specific application can significantly impact system performance, energy efficiency, and operational safety. This buyer’s guide explains the key factors to consider when choosing an AI hydraulic control valve and highlights how companies like Dongguan Mingyuda Electronic Technology Co., Ltd. support these systems with precision components and reliable solutions.

1. Understand Your Application Requirements

Before selecting an AI hydraulic control valve, it’s critical to define your application parameters:

Operating pressure and flow rate: Ensure the valve can handle the expected hydraulic load.

System complexity: Multi-axis machines or advanced robotic systems may require more responsive valves.

Environmental conditions: High temperature, corrosive media, or vibration-heavy environments influence valve material and design choices.

A clear understanding of these factors helps narrow down suitable options and ensures optimal performance.

2. Consider the Valve Type and Configuration

AI hydraulic valves come in various configurations, including proportional valves, servo valves, and directional control valves. Key considerations include:

Proportional valves: Ideal for smooth, variable flow control.

Servo valves: Offer high precision and rapid response for dynamic loads.

Directional control valves: Efficiently manage complex fluid routing in multi-cylinder or multi-motor systems.

Choosing the right configuration ensures that your system operates efficiently and responds accurately to AI-driven control inputs.

3. Look for Integrated AI Features

Not all hydraulic valves are created equal — the AI component is crucial. Modern AI hydraulic valves offer:

Self-adjusting flow and pressure control based on real-time system feedback.

Predictive maintenance capabilities that alert operators to potential issues before failure occurs.

Adaptive learning algorithms that optimize performance over time, reducing energy consumption and wear.

Valves equipped with these features enable smarter, more responsive automation systems.

4. Material and Build Quality

High-quality construction is essential for reliability and longevity. Key aspects to consider:

Corrosion-resistant materials for harsh environments.

Precision-machined components to reduce leakage and ensure consistent flow.

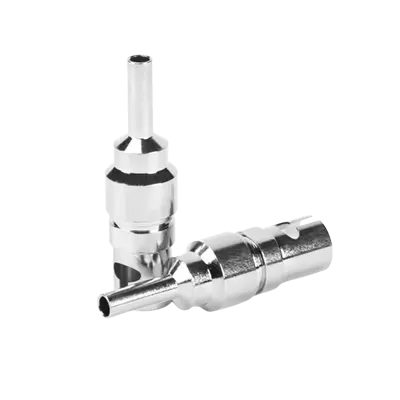

Durable seals and connectors to maintain system integrity under high pressure.

Dongguan Mingyuda Electronic Technology Co., Ltd. supports these requirements by manufacturing precision hardware, including spring pins, crown pins, connector pins, screws, nuts, cable sealing sleeves, aviation connector terminals, and custom-shaped terminals. These components ensure secure, reliable connections in hydraulic control systems and help maintain overall valve performance.

5. Actuation and Integration

AI hydraulic valves often need to integrate seamlessly with your broader automation system. Consider:

Compatibility with sensors and controllers to enable real-time feedback loops.

Electrical and mechanical connection standards to simplify installation.

Valve accessories such as feedback sensors, manual overrides, or solenoid controls for enhanced functionality.

Mingyuda’s expertise in metal terminal assemblies, sensor components, and precision connectors ensures that AI valves can integrate smoothly into complex automation setups.

6. Maintenance and Serviceability

Choose a valve that is easy to maintain and offers access to replacement parts and technical support. Features that aid maintenance include:

Modular design for quick part replacement

Standardized connection points for easy servicing

Support from experienced manufacturers for diagnostics and repair

Reliable maintenance ensures continuous operation and minimizes costly downtime.

7. Supplier Reliability

Partnering with a trusted supplier is just as important as selecting the right valve. Look for manufacturers that offer:

Proven track records in industrial automation

Comprehensive technical support

Custom component solutions to match your application needs

Dongguan Mingyuda Electronic Technology Co., Ltd. is a prime example of a reliable partner. By providing precision connectors, spring pins, sensor assemblies, and other high-quality components, Mingyuda ensures that AI hydraulic systems function reliably in demanding industrial environments.

Conclusion

Selecting the right AI hydraulic control valve requires careful consideration of system requirements, valve type, AI features, material quality, integration, maintenance, and supplier reliability. By focusing on these key factors, manufacturers can ensure optimal performance, energy efficiency, and long-term system reliability.

With support from trusted component suppliers like Dongguan Mingyuda Electronic Technology Co., Ltd., businesses can confidently implement AI-driven hydraulic solutions, achieving smarter automation and improved operational outcomes.