Position:Home > News > Industry News > How to Choose a Reliable Circular Connector Accessories Factory for Industrial Applications

How to Choose a Reliable Circular Connector Accessories Factory for Industrial Applications

Circular connectors are widely used in industrial automation, aerospace, medical devices, transportation, and energy systems. While the connector itself often receives most of the attention, connector accessories—such as contacts, housings, fasteners, seals, and terminals—play a critical role in performance, reliability, and service life.

Selecting a reliable circular connector accessories factory is therefore a strategic decision for manufacturers and OEMs. The right partner ensures consistent quality, application compatibility, and long-term supply stability, while the wrong choice can lead to failures, delays, and costly rework.

Understand the Factory’s Core Manufacturing Capabilities

A reliable factory should demonstrate strong expertise in precision metal components, not just basic assembly. Circular connector accessories demand tight tolerances, stable conductivity, and mechanical durability.

Key capabilities to look for include:

Precision stamping and machining

High-consistency metal forming processes

Surface treatment and plating control

Ability to handle small, complex connector parts

Dongguan Mingyuda Electronic Technology Co., Ltd. focuses on the research and development of precision metal components for connectors, offering engineering-driven solutions rather than standard off-the-shelf parts. This capability is especially important for industrial applications with demanding performance requirements.

Evaluate Product Range and Application Coverage

A qualified circular connector accessories factory should support multiple industries and connector systems, not just a narrow product line. A broader product range often reflects deeper technical experience and stronger process control.

Typical connector accessories include:

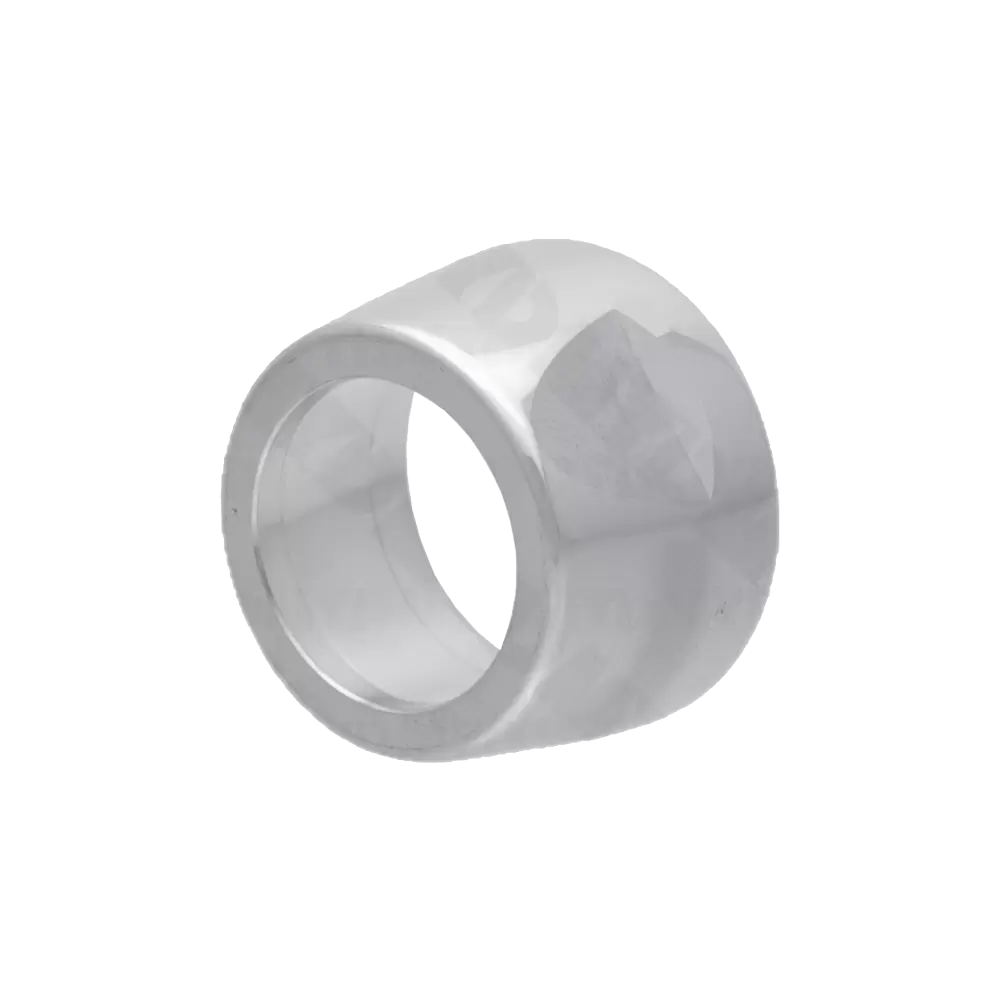

Spring pins and crown spring contacts

Precision connector pins and terminals

Connector housing screws and nuts

Cable glands and sealing components

Aviation connector terminals and custom-shaped contacts

Mingyuda designs and manufactures a wide variety of products, including spring pins, precision connector pins, connector housing fasteners, cable sealing components, aviation connector terminals, and customized metal terminals. This diversity allows industrial customers to consolidate sourcing and ensure compatibility across different connector systems.

Customization and Engineering Support Matter

Industrial applications rarely rely on generic components alone. Custom pin structures, special materials, or unique terminal shapes are often required to meet electrical, mechanical, or environmental demands.

When evaluating a factory, assess whether it can:

Support custom drawings and prototypes

Optimize designs for manufacturability

Recommend materials based on application conditions

Deliver consistent quality during mass production

Factories with in-house engineering teams can provide more than parts—they offer system-level solutions that reduce development cycles and improve final product reliability.

Quality Control and Process Consistency

Connector accessories are small components, but even minor defects can cause signal instability, poor contact resistance, or mechanical failure. A reliable factory must maintain strict quality control throughout the production process.

Important quality indicators include:

Raw material inspection and traceability

In-process dimensional checks

Electrical and mechanical performance testing

Stable batch-to-batch consistency

For industrial and medical applications, these controls are especially critical, as component failure can lead to equipment downtime or safety risks.

Industry Experience and End-Use Knowledge

Factories that serve multiple sectors tend to have stronger problem-solving capabilities. Experience in demanding fields such as aerospace, medical devices, and industrial automation reflects a higher level of process maturity.

Dongguan Mingyuda Electronic Technology Co., Ltd. manufactures not only connector accessories but also metal terminal sensor components, medical device accessories, and cable stamping parts. This cross-industry experience enables the company to understand diverse application environments and performance expectations.

Supply Stability and Long-Term Partnership

For OEMs and industrial manufacturers, supply reliability is just as important as initial product quality. A dependable circular connector accessories factory should offer:

Stable production capacity

Scalable output as demand grows

Clear communication and lead-time control

Long-term support for ongoing projects

Working directly with a capable factory reduces dependency on intermediaries and helps maintain consistent specifications over the product lifecycle.

Conclusion

Choosing a reliable circular connector accessories factory requires more than comparing prices. Manufacturers should evaluate technical capabilities, product diversity, customization support, quality systems, and industry experience.

Factories like Dongguan Mingyuda Electronic Technology Co., Ltd., which focus on precision connector metal components and system-level solutions, provide industrial customers with the reliability and flexibility needed for complex applications. By selecting the right partner, businesses can improve product performance, reduce risk, and build a stronger foundation for long-term growth.