Position:Home > News > Industry News > How to Choose the Right Circular Connector Accessories for Harsh Environments

How to Choose the Right Circular Connector Accessories for Harsh Environments

In industries such as aerospace, automotive, energy, and heavy equipment manufacturing, circular connectors are a critical part of ensuring reliable performance under extreme conditions. But what often gets overlooked is the vital role circular connector accessories play in maintaining integrity, safety, and longevity—especially in harsh environments that involve moisture, vibration, dust, and temperature extremes.

Choosing the right accessories isn't just about compatibility—it's about survival. In this guide, we’ll walk you through what to consider when selecting circular connector accessories for rugged conditions, and why working with a precision manufacturer like Dongguan Mingyuda Electronic Technology Co., Ltd. gives your systems a long-term advantage.

1. Understand the Environmental Challenges

Before selecting accessories, assess the specific environmental threats:

Moisture or Submersion? You’ll need IP-rated cable sealing glands and waterproof backshells.

Extreme Heat or Cold? Thermal-resistant insulators and materials are a must.

Frequent Vibration or Impact? Go for locking screws, secure fastening systems, and vibration-proof terminals.

Dusty or Corrosive Areas? Choose corrosion-resistant metallic housings and dustproof seals.

Dongguan Mingyuda specializes in precision-engineered metal terminals, cable glands, sensor components, and connector hardware that meet the mechanical demands of challenging applications.

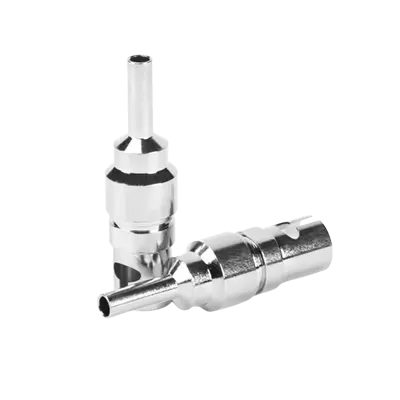

2. Prioritize Seal Integrity and Cable Protection

One of the most crucial elements in rugged connector systems is sealing. Without high-performance sealing accessories, water or particles can enter and compromise the entire system.

Mingyuda offers custom cable sealing sleeves and cable strain relief accessories that enhance environmental protection for circular connectors—ideal for marine, outdoor, and medical device applications.

3. Material Matters: Choose Durability Over Cost

Plastic accessories might work in basic environments, but harsh conditions demand metal—especially brass, stainless steel, or plated aluminum. These materials offer superior:

Corrosion resistance

Mechanical durability

Electromagnetic shielding

Mingyuda’s precision-machined screws, nuts, and connector housings are manufactured with industrial-grade materials to ensure resistance to corrosion, thermal cycling, and pressure changes.

4. Look for Customization for Specialized Needs

Not all circular connector setups are alike—custom environments require custom solutions. Look for suppliers who can tailor accessories to:

Unique shapes and form factors

Specific cable diameters or connector layouts

Medical-grade or sensor-grade tolerances

Industry certifications (e.g., RoHS, REACH)

Dongguan Mingyuda excels in custom-shaped terminals, sensor assembly components, and precision cable stamping parts, enabling seamless integration even in the most unconventional systems.

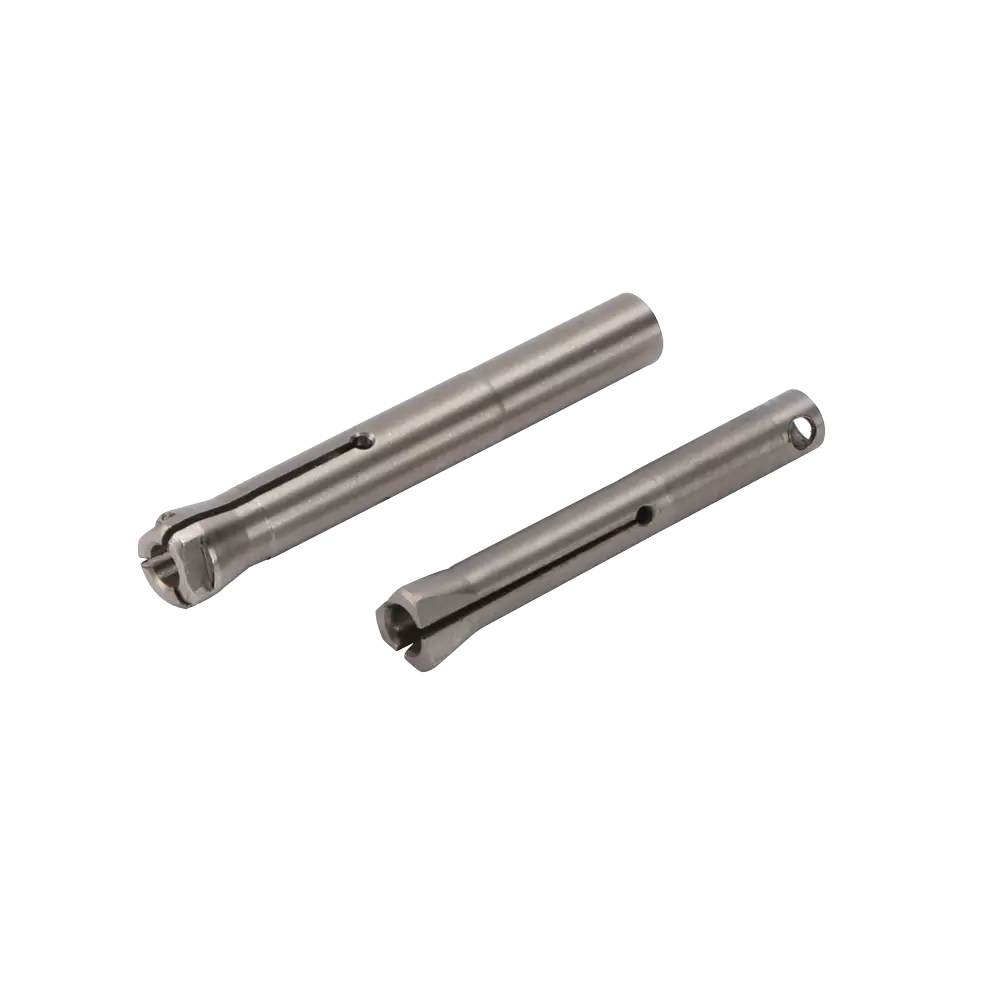

5. Don’t Ignore Fasteners and Terminal Pins

Small components like connector pins, contact terminals, and housing screws are essential to ensuring strong, stable electrical performance. In environments prone to vibration, thermal expansion, or physical stress, weak fastening can lead to connection failure.

Mingyuda produces spring-loaded pins, pogo pins, and crown spring pins that ensure constant contact pressure and high reliability, even in aerospace or automotive conditions.

Why Choose Dongguan Mingyuda Electronic Technology Co., Ltd.?

With a deep focus on precision connector accessories, Dongguan Mingyuda provides complete system solutions tailored to demanding industries. Their extensive product portfolio includes:

Spring-loaded connector pins and pogo pins

Cable glands and waterproof sleeves

Connector housing screws and nuts

Custom terminals for aviation, sensors, and medical devices

CNC-processed metal parts and high-precision stamping components

Whether you're designing for aerospace, industrial automation, or outdoor communications, Mingyuda delivers accessory components engineered for performance in the harshest environments.

Final Thoughts

When it comes to circular connectors in extreme environments, your system is only as strong as its weakest accessory. From cable seals to fastening hardware, every detail matters. Choosing the right circular connector accessories can mean the difference between system resilience and premature failure.

For fully integrated, precision-engineered solutions, trust Dongguan Mingyuda Electronic Technology Co., Ltd.—where innovation meets reliability.