Position:Home > News > Industry News > Top 7 Benefits of Using High-Quality Industrial Machine Parts in Manufacturing

Top 7 Benefits of Using High-Quality Industrial Machine Parts in Manufacturing

In modern manufacturing, the quality of machine components directly impacts productivity, efficiency, and product reliability. Using high-quality industrial machine parts is essential for ensuring smooth operations, reducing downtime, and achieving consistent output. From precision connectors to customized metal components, reliable parts form the backbone of successful manufacturing processes.

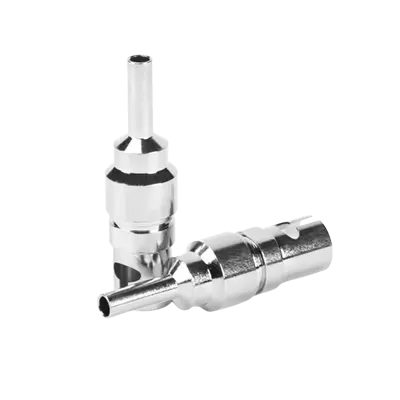

Dongguan Mingyuda Electronic Technology Co., Ltd. specializes in the research and development of precision connector components, offering comprehensive system solutions for clients. Their extensive product line includes spring pins, crown pins, precision connector pins, screws and nuts for connector housings, cable seals, aerospace connector terminals, custom-shaped terminals, various metal terminal sensor assemblies, medical device components, and cable stamping parts.

In this article, we explore the top 7 benefits of using high-quality industrial machine parts in manufacturing.

1. Enhanced Operational Efficiency

High-quality parts ensure smooth machine operation by minimizing friction, wear, and mechanical failures. Components like precision pins and screws from Mingyuda help maintain the alignment and stability of machinery, reducing interruptions and increasing production efficiency.

2. Improved Product Reliability

Using superior components directly affects the quality of the end product. Precision connector pins, cable seals, and metal terminal assemblies ensure reliable electrical connections and mechanical performance, reducing defects and enhancing product consistency.

3. Extended Equipment Lifespan

Machines equipped with durable, high-grade parts experience less wear and tear, extending the lifespan of equipment. Parts such as crown pins and custom metal terminals from Mingyuda are manufactured with strict quality standards, ensuring long-term reliability and reducing the frequency of replacements.

4. Reduced Maintenance Costs

Investing in high-quality components can significantly lower maintenance costs. Reliable parts decrease the likelihood of unexpected breakdowns, minimize downtime, and reduce labor and replacement expenses. Mingyuda’s precision components are engineered to perform consistently under demanding industrial conditions.

5. Enhanced Safety in Manufacturing

High-quality industrial parts reduce the risk of equipment malfunctions, which can lead to workplace accidents. By using certified, precision-engineered components such as aerospace connector terminals and medical device parts, manufacturers create a safer working environment for operators.

6. Greater Flexibility for Custom Applications

Modern manufacturing often requires tailored solutions. Companies like Mingyuda provide custom-shaped terminals, specialized connector pins, and cable assemblies, allowing manufacturers to adapt machines for unique applications while maintaining high performance.

7. Compliance with Industry Standards

High-quality industrial parts are often manufactured to meet stringent international standards. Using certified components ensures compliance with industry regulations, whether for aerospace, medical, electronics, or other specialized sectors. Mingyuda’s products adhere to rigorous standards, offering peace of mind to manufacturers.

Conclusion

Investing in high-quality industrial machine parts is a strategic decision that improves efficiency, reliability, safety, and overall productivity in manufacturing. From precision connector pins to customized metal assemblies, the quality of each component affects the performance of the entire production line.

Dongguan Mingyuda Electronic Technology Co., Ltd. delivers precision-engineered components and system solutions that meet the demanding needs of modern manufacturing. Their wide range of products—including spring pins, crown pins, connector pins, screws, cable seals, aerospace terminals, custom terminals, and medical device components—helps manufacturers achieve operational excellence and maintain a competitive edge.

By integrating high-quality industrial machine parts from a trusted supplier like Mingyuda, businesses can ensure consistent performance, reduce downtime, and enhance product quality, ultimately supporting long-term growth and efficiency in manufacturing operations.