Position:Home > News > Industry News > How to Choose the Right Optical Accessories for Precision Applications

How to Choose the Right Optical Accessories for Precision Applications

In the fields of photonics, telecommunications, medical imaging, and advanced manufacturing, precision is everything. Even the smallest optical misalignment or inconsistency can affect system accuracy, signal clarity, and overall performance. That’s why choosing the right optical accessories is critical to any high-precision application.

Whether you're building a fiber optic communication system, a scientific instrument, or a high-resolution imaging device, your components must meet strict demands for reliability, tolerance, and durability. In this article, we’ll explore how to choose the right optical accessories and how precision component manufacturers like Dongguan Mingyuda Electronic Technology Co., Ltd. support this need with comprehensive, custom-engineered solutions.

What Are Optical Accessories?

Optical accessories are specialized components used in systems involving light manipulation, such as focusing, filtering, guiding, or connecting light signals. These accessories may include:

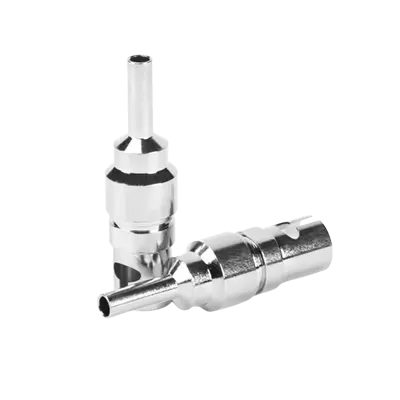

Fiber optic connectors and adapters

Optical lens holders and mounts

Cable sealing components

Precision terminals and pins for optical sensor modules

Connector housings and metal accessories

Laser diode modules and alignment tools

These parts are critical in ensuring proper alignment, signal transmission, shielding, and mechanical stability in advanced optical systems.

Key Considerations When Choosing Optical Accessories

1. Application Requirements

Start by identifying the specific needs of your application:

Telecommunications may require low-loss fiber connectors and high-speed data compatibility

Medical devices need biocompatible materials and precision contact points

Industrial sensors demand vibration-resistant and sealed components

Aerospace and military applications require ruggedized, high-tolerance fittings

Understanding these demands helps determine which accessory materials, tolerances, and configurations are most suitable.

2. Precision and Tolerance

In optical systems, micrometer-level accuracy can make or break performance. Always select components with tight mechanical tolerances to ensure optical alignment and repeatable performance, especially for connectors, pins, or sensor terminals.

Dongguan Mingyuda Electronic Technology Co., Ltd. specializes in manufacturing precision connector pins, spring-loaded contacts, and terminal components designed to meet high-tolerance specifications, ensuring consistency even in critical environments.

3. Material Compatibility

Material choice affects everything from signal integrity to corrosion resistance and thermal stability. Common materials include:

Stainless steel for strength and resistance

Copper alloys for conductivity

Medical-grade plastics or polymers for insulation and bio-compatibility

Mingyuda offers a wide range of materials tailored to specific application requirements, including cable sealing components and terminal assemblies for both standard and custom designs.

4. Environmental Resistance

Consider whether the optical accessories will be exposed to:

Moisture or dust (requiring sealed or IP-rated components)

Temperature extremes (requiring thermal stability)

Vibration or mechanical stress (requiring shock-absorbent or reinforced designs)

The company’s expertise in developing sensor components, aviation connector terminals, and cable stamping parts ensures reliability in even the most demanding conditions.

5. Customization and Integration

If your system demands unique shapes, installation methods, or combined functions, work with a manufacturer that offers customized solutions.

Mingyuda’s team of engineers works closely with clients to design and prototype optical accessory components tailored to exact system needs, offering end-to-end support from concept to final delivery.

Why Partner with Dongguan Mingyuda Electronic Technology Co., Ltd.?

With years of experience in precision connector hardware development, Dongguan Mingyuda provides more than just standard parts. The company offers:

A wide portfolio of precision components, including spring-loaded pins, connector terminals, screws, sealing nuts, and more

Advanced manufacturing capabilities to support medical, aerospace, automotive, and optical systems

Custom system solutions with in-house R&D, design, prototyping, and production

High-quality standards to ensure consistent performance and product integrity

Whether you need high-frequency signal connectors or ruggedized optical sensor terminals, Mingyuda delivers reliable components that support high-precision and high-performance applications worldwide.

Final Thoughts

Choosing the right optical accessories isn't just about technical specifications—it’s about system performance, durability, and long-term reliability. In complex environments where precision matters, every detail counts.

By working with an experienced partner like Dongguan Mingyuda Electronic Technology Co., Ltd., you gain access to customized, high-quality optical components engineered for your specific industry demands.

For designers and engineers building the future of optics, precision starts with the right components—and the right partner.