Position:Home > News > Industry News > How Dedicated Sensors Hardware Improves Reliability in Smart Manufacturing Systems

How Dedicated Sensors Hardware Improves Reliability in Smart Manufacturing Systems

Smart manufacturing systems rely on real-time data, precise control, and seamless communication between machines. Sensors are at the core of these systems, providing critical information that enables automation, predictive maintenance, and quality control. To ensure long-term stability and accuracy, dedicated sensors hardware has become an essential component in modern smart manufacturing environments.

Dongguan Mingyuda Electronic Technology Co., Ltd. focuses on the research and development of precision connector metal components and provides comprehensive system solutions for customers worldwide. Through high-quality sensor-related hardware and customized metal components, Mingyuda supports the reliability and performance of smart manufacturing systems across multiple industries.

The Importance of Reliability in Smart Manufacturing

In smart factories, even minor data inaccuracies can lead to production errors, equipment damage, or unplanned downtime. Reliable sensor performance is crucial for monitoring parameters such as temperature, pressure, position, and electrical signals. Dedicated sensors hardware is specifically designed to deliver consistent and accurate data, even under continuous operation and challenging industrial conditions.

By separating sensing functions from other electronic systems, dedicated hardware reduces interference and enhances overall system stability.

Dedicated Sensors Hardware vs General-Purpose Solutions

General-purpose or integrated sensor solutions may offer compact designs, but they often face limitations in durability and customization. Dedicated sensors hardware, on the other hand, uses specialized components optimized for sensing tasks, allowing for higher precision and better resistance to vibration, heat, and electromagnetic interference.

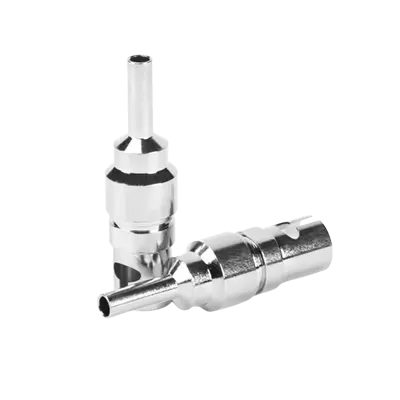

Precision metal terminals, stable contact structures, and robust housings ensure secure electrical connections and reliable signal transmission over long operating cycles.

The Role of Precision Metal Components

High-quality metal components are fundamental to the reliability of dedicated sensors hardware. Elements such as spring pins, crown spring pins, and precision connector pins provide consistent contact force and low contact resistance, which are essential for accurate signal transmission.

Dongguan Mingyuda Electronic Technology Co., Ltd. designs and manufactures a wide range of precision components, including customized sensor terminals, aviation connector contacts, cable sealing glands, and metal sensor components. These parts help maintain stable electrical performance and mechanical strength in smart manufacturing environments.

Enhancing System Stability and Reducing Downtime

Dedicated sensors hardware improves system stability by minimizing signal loss and mechanical failure. Reliable connectors and terminals reduce the risk of loose connections, corrosion, or wear, which are common causes of sensor malfunction.

In smart manufacturing systems that operate continuously, reduced downtime directly translates into higher productivity and lower maintenance costs. Mingyuda’s precision metal parts are engineered to support long service life and consistent performance, helping manufacturers maintain uninterrupted operations.

Supporting Customization and Scalability

Smart manufacturing systems often require customized sensor configurations to match specific production processes. Dedicated sensors hardware allows for flexible design and easy integration into different equipment setups.

With expertise in producing custom-shaped terminals, sensor metal components, and cable stamping parts, Dongguan Mingyuda Electronic Technology Co., Ltd. supports system-level customization, enabling manufacturers to scale and adapt their sensing solutions as production needs evolve.

Applications Beyond Industrial Automation

While smart manufacturing is a key application, dedicated sensors hardware is also widely used in medical equipment, testing instruments, and high-precision electronic systems. In these fields, reliability and accuracy are equally critical.

Mingyuda’s product range extends to medical device accessories and high-precision connectors, highlighting the broad applicability of dedicated sensor hardware components across multiple industries.

Conclusion

Dedicated sensors hardware plays a vital role in improving reliability within smart manufacturing systems. By delivering accurate data, stable signal transmission, and durable performance, it supports efficient automation, predictive maintenance, and consistent product quality.

Through its focus on precision connector metal components and comprehensive system solutions, Dongguan Mingyuda Electronic Technology Co., Ltd. contributes to the development of reliable, high-performance sensing hardware for smart manufacturing and beyond. Investing in dedicated sensors hardware is a strategic step toward building smarter, more resilient industrial systems.