Position:Home > News > Industry News > Top Advantages of Buying Wholesale Precision Machining Hardware for Your Business

Top Advantages of Buying Wholesale Precision Machining Hardware for Your Business

In today’s fast-paced manufacturing and electronics industries, precision machining hardware plays a critical role in ensuring the efficiency, durability, and quality of end products. Whether you’re in automotive, aerospace, medical devices, telecommunications, or consumer electronics, sourcing high-quality hardware components can directly impact your competitiveness in the market. One of the most effective strategies for businesses is buying wholesale precision machining hardware—a practice that provides not only cost savings but also long-term advantages in scalability and reliability.

Cost Efficiency Through Bulk Purchasing

One of the most obvious benefits of wholesale purchasing is cost efficiency. When you buy precision machining hardware in bulk, suppliers often offer discounted rates, enabling businesses to reduce per-unit costs significantly. This is particularly important for manufacturers who require large quantities of components such as pins, terminals, screws, or nuts. Lower costs mean better margins and improved flexibility in pricing strategies.

Consistency in Product Quality

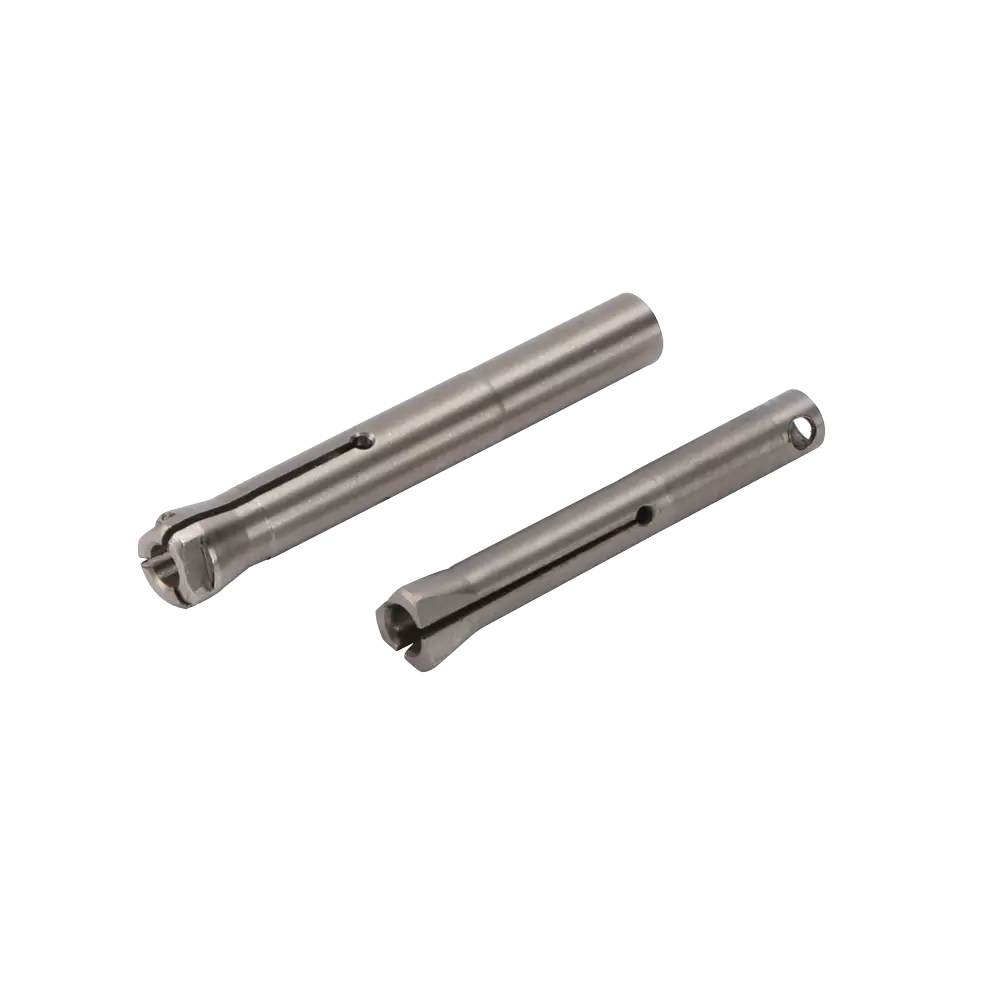

Consistency is crucial in industries where precision determines performance and safety. By purchasing from reliable wholesale suppliers, businesses ensure uniform standards across all components. For instance, Dongguan Mingyuda Electronic Technology Co., Ltd. has dedicated itself to the R&D and production of precision machining hardware and connector components. Their portfolio includes spring pins, crown spring pins, precision connector pins, screws and nuts for connector housings, cable glands, aviation connector terminals, custom-shaped terminals, various sensor components, as well as medical device accessories and stamped cable parts. Such consistency guarantees that every batch meets the same stringent quality requirements.

Streamlined Supply Chain and Availability

When companies partner with wholesale suppliers, they gain access to a stable and reliable supply chain. This helps avoid production delays caused by shortages of critical parts. Having a wholesale arrangement also provides peace of mind that even during peak production cycles, there is adequate inventory to meet demand. With global logistics partners like Dongguan Mingyuda, businesses can rest assured that they will have timely access to the hardware they need.

Customization and Specialized Solutions

Wholesale precision machining hardware suppliers are often equipped to provide customized solutions for unique project requirements. This goes beyond standard catalog products, allowing businesses to access custom connector pins, terminals, and sensor components tailored to their designs. Mingyuda, for example, offers extensive engineering support to help customers develop tailored system solutions, ensuring that components integrate seamlessly into their applications.

Supporting Innovation and Market Competitiveness

When businesses secure high-quality wholesale precision machining hardware, they can focus more on innovation and less on component sourcing challenges. Reliable suppliers become strategic partners, helping companies stay ahead of competitors. Whether developing next-generation electronics, advanced medical devices, or aerospace-grade systems, having dependable hardware components ensures that products perform as expected.

Long-Term Business Relationships and Support

Finally, wholesale arrangements foster long-term partnerships between manufacturers and suppliers. This not only ensures steady quality and pricing but also unlocks additional services like technical consultation, product updates, and access to new innovations in machining technology. Companies like Dongguan Mingyuda are committed to building long-term cooperation with clients by offering comprehensive system solutions, continuous support, and scalable production capabilities.

Conclusion

Incorporating wholesale strategies for sourcing precision machining hardware offers businesses a competitive edge through cost savings, product consistency, supply stability, and access to custom solutions. Partnering with experienced suppliers like Dongguan Mingyuda Electronic Technology Co., Ltd. ensures not only reliable hardware components but also long-term collaboration for innovation and growth. For companies looking to thrive in demanding industries, wholesale precision machining hardware is not just a purchasing decision—it’s a strategic investment.