Position:Home > News > Industry News > How to Choose the Right Supplier for High-Precision Industrial Machined Parts

How to Choose the Right Supplier for High-Precision Industrial Machined Parts

In today’s competitive manufacturing landscape, high-precision industrial machined parts play a crucial role in ensuring performance, reliability, and product quality across industries such as electronics, aerospace, automotive, and medical technology. Choosing the right supplier for these components is not just about cost—it’s about finding a partner who can deliver accuracy, consistency, and innovation at every stage of production.

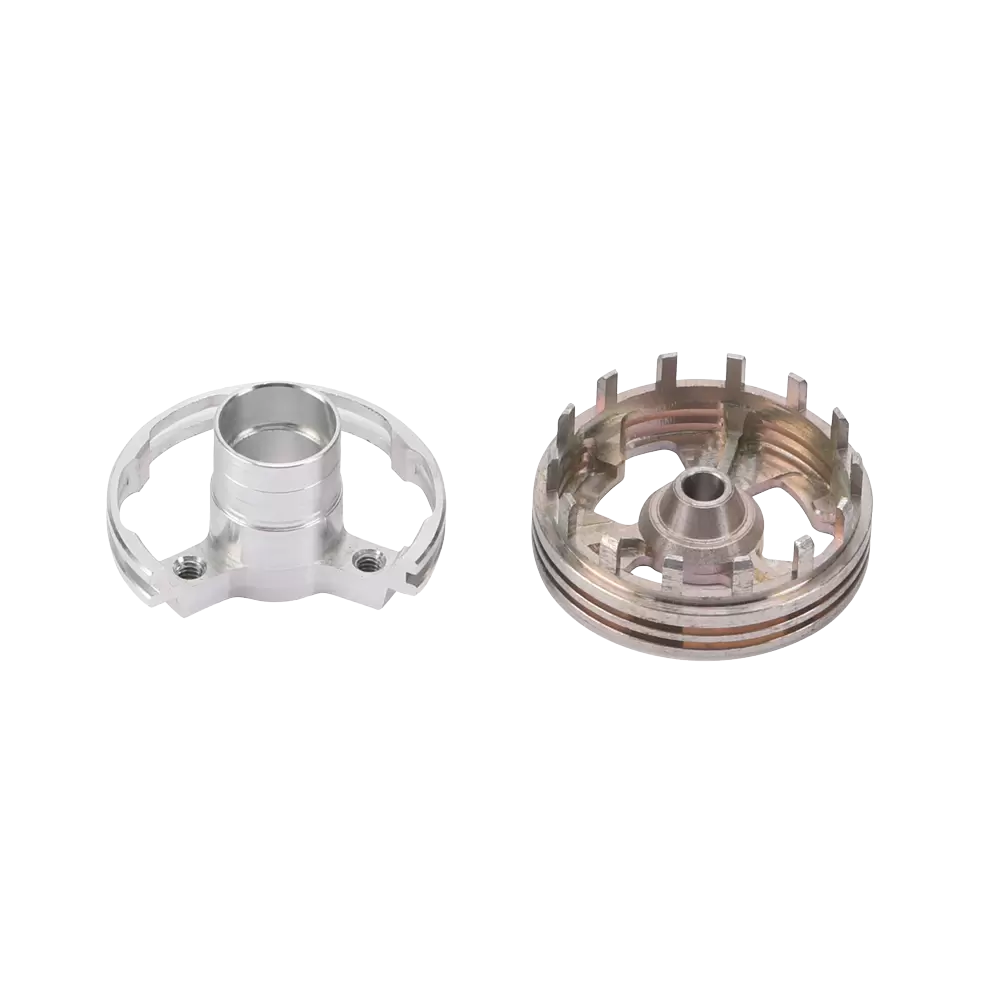

One such trusted manufacturer is Dongguan Mingyuda Electronic Technology Co., Ltd., a company dedicated to the R&D and production of precision connector hardware components. With a strong focus on engineering excellence and customization, Mingyuda designs and manufactures a wide range of products including spring pins, crown spring pins, precision connector pins, screws and nuts for connector housings, cable glands, aviation connector terminals, custom-shaped terminals, various metal sensor components, medical device accessories, and cable stamping parts.

Whether you’re sourcing components for electronic connectors, industrial sensors, or medical systems, selecting the right supplier can make all the difference. Below are key factors to consider when choosing a high-precision industrial machined parts supplier.

1. Evaluate Technical Expertise and Manufacturing Capabilities

The precision and complexity of industrial machined parts demand advanced manufacturing equipment and skilled engineering teams. A reliable supplier should have in-depth knowledge of materials, tolerances, and machining technologies.

Dongguan Mingyuda Electronic Technology Co., Ltd. stands out for its strong technical foundation, integrating precision machining, stamping, and custom design capabilities. Their continuous investment in advanced CNC machines and quality inspection systems ensures that every product meets exact technical specifications, no matter how complex the design.

When evaluating a potential supplier, ask about:

CNC and EDM equipment capabilities

Production tolerances (e.g., ±0.01 mm or finer)

Experience with multi-axis machining

Capability to handle prototype and large-scale production

2. Focus on Quality Assurance and Certification

Quality assurance is the backbone of precision manufacturing. Even a minor deviation can lead to performance failures in high-tech applications. Look for suppliers with strict quality management systems and relevant industry certifications.

Mingyuda implements comprehensive quality control procedures, including material verification, in-process inspection, and final product testing. Their precision components undergo rigorous measurement checks to guarantee dimensional accuracy, surface finish, and mechanical integrity.

Certifications such as ISO 9001 or IATF 16949 are key indicators that a supplier maintains international standards of quality control and continuous improvement.

3. Assess Material Selection and Customization Capabilities

Different applications require different materials—from stainless steel and copper alloys to titanium and high-strength aluminum. A dependable supplier should be capable of working with diverse materials and providing custom solutions based on your project’s specific requirements.

Mingyuda’s expertise in designing custom metal terminals, precision connector pins, and sensor components allows them to adapt to various material and plating demands, ensuring optimal electrical conductivity, corrosion resistance, and mechanical durability.

Customization should extend beyond the component itself to include packaging, labeling, and delivery flexibility that fits your production schedule.

4. Consider the Supplier’s Engineering Support and Design Collaboration

For many businesses, the best suppliers are not just manufacturers—they’re engineering partners. Early-stage collaboration can help optimize part design for manufacturability, reducing costs and improving product performance.

Dongguan Mingyuda Electronic Technology Co., Ltd. provides end-to-end system solutions, from design consultation to prototype development and mass production. Their R&D team works closely with customers to refine structural designs, material usage, and production processes, ensuring that every machined component aligns perfectly with system-level requirements.

Strong engineering support can save time, minimize redesign cycles, and enhance overall production efficiency.

5. Review Production Scalability and Delivery Efficiency

Timely delivery and scalability are essential when selecting an industrial machined parts supplier. Whether your project requires low-volume precision prototypes or large-batch production, the supplier must be able to scale operations without compromising quality.

With a streamlined production management system and an efficient supply chain, Mingyuda ensures on-time delivery of both standard and customized components. Their experience serving global customers across electronics, telecommunications, and medical industries enables them to manage complex orders with precision and reliability.

6. Evaluate Communication, Service, and Long-Term Partnership Potential

The best supplier relationships are built on transparent communication and long-term collaboration. A responsive and service-oriented partner will provide regular updates, technical support, and fast issue resolution—ensuring that your production line runs smoothly.

Mingyuda’s customer-first approach emphasizes open communication, fast quotation turnaround, and dedicated after-sales service. Their goal is not just to deliver parts, but to create enduring partnerships that help clients succeed in competitive global markets.

Conclusion

Selecting the right supplier for high-precision industrial machined parts is a strategic decision that affects every aspect of your product’s performance and profitability. Key evaluation criteria—such as technical expertise, quality assurance, customization, scalability, and service reliability—should guide your choice.

With its strong R&D capabilities, advanced machining technology, and commitment to customer satisfaction, Dongguan Mingyuda Electronic Technology Co., Ltd. represents a trusted global partner for precision component solutions. Whether your needs involve connector pins, aviation terminals, sensor parts, or custom metal components, Mingyuda’s precision manufacturing expertise ensures consistent quality, innovation, and value in every product delivered.