Position:Home > News > Industry News > How to Choose High-Quality Industrial Machining Parts for Your Manufacturing Needs

How to Choose High-Quality Industrial Machining Parts for Your Manufacturing Needs

In modern manufacturing, the quality of industrial machining parts directly impacts product reliability, performance, and safety. Whether you are producing electronic devices, automotive systems, aerospace equipment, or medical devices, selecting the right machining components is critical to maintaining efficiency and staying competitive. With countless suppliers on the market, knowing how to choose high-quality parts can save you time, money, and long-term risks.

One leading example is Dongguan Mingyuda Electronic Technology Co., Ltd., a company dedicated to the research, design, and production of precision connector hardware components. By offering a comprehensive range of solutions, Mingyuda has become a trusted partner for industries that demand precision and innovation.

Why Quality Matters in Industrial Machining Parts

Choosing inferior machining parts may seem cost-effective in the short term, but it often leads to:

Increased failure rates

Higher maintenance costs

Product recalls or compliance issues

Negative brand reputation

On the other hand, high-quality machining parts:

Ensure durability and long service life

Provide precise performance under demanding conditions

Reduce downtime and production delays

Comply with international industry standards

Key Factors to Consider When Choosing Industrial Machining Parts

1. Material Selection

High-quality materials determine the strength, conductivity, and resistance of machining parts. For example:

Connector pins and terminals require excellent conductivity and corrosion resistance.

Fasteners such as screws and nuts must withstand mechanical stress.

Cable sealing sleeves should be durable and resistant to environmental exposure.

2. Precision and Tolerance Levels

In industries such as aerospace, automotive, and medical devices, even the smallest deviation can cause system failure. Always check whether the supplier provides tight tolerances and high-precision machining.

3. Customization Capabilities

Every industry has unique requirements. Manufacturers that offer customized machining parts—such as specially shaped terminals, medical device accessories, or cable stamping components—ensure a better fit for your production needs.

4. Compliance and Certification

Reliable suppliers ensure their machining parts meet international quality and safety standards, which is essential for global trade and product approvals.

5. Supplier Experience and Innovation

Partnering with an experienced supplier not only guarantees consistency but also opens the door to innovative designs and integrated solutions.

How Dongguan Mingyuda Electronic Technology Co., Ltd. Delivers Quality

Dongguan Mingyuda Electronic Technology Co., Ltd. excels in providing comprehensive machining solutions with a focus on connector precision hardware. Their expertise includes:

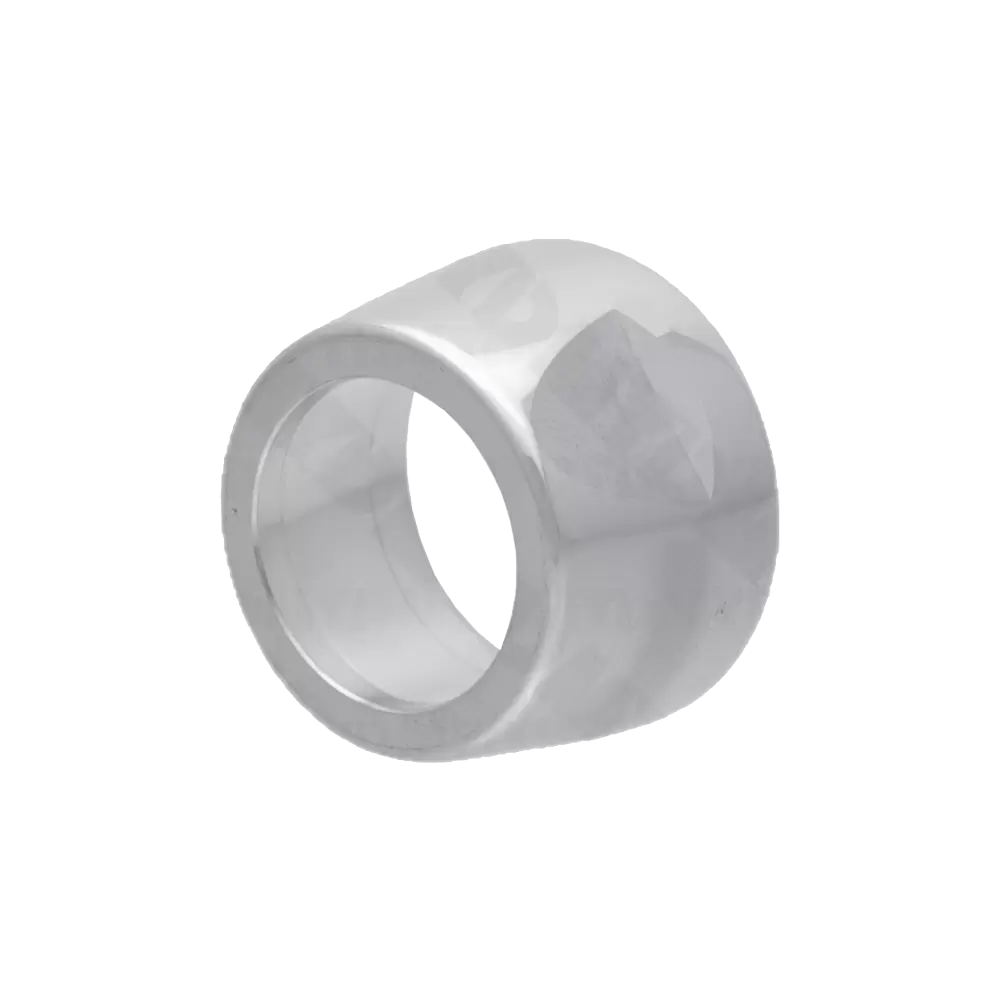

Spring pins, crown spring pins, and precision connector pins for reliable electrical connections.

Screws and nuts for connector housings, ensuring stability and strength.

Cable sealing sleeves for protection in harsh industrial environments.

Aerospace connector terminals and customized terminal shapes for specialized applications.

Metal terminal sensor components widely used in automotive and industrial systems.

Medical device accessories and cable stamping parts tailored for the healthcare sector.

By integrating R&D, design, and manufacturing, Mingyuda provides clients with end-to-end system solutions. Their commitment to innovation and precision makes them a preferred partner for businesses that value quality and reliability.

Practical Tips for Selecting the Right Supplier

Request Samples and Inspection Reports before committing to bulk orders.

Evaluate manufacturing capacity to ensure timely delivery.

Check customer reviews and references for credibility.

Confirm customization capabilities if your project requires specialized parts.

Build long-term partnerships with suppliers who consistently deliver quality and innovation.

Conclusion

Choosing high-quality industrial machining parts is not just about cost—it’s about long-term performance, safety, and efficiency. By focusing on material quality, precision, customization, compliance, and supplier expertise, manufacturers can ensure their products meet the highest industry standards.

With its strong dedication to precision connector components, innovative R&D, and customized solutions, Dongguan Mingyuda Electronic Technology Co., Ltd. stands out as a reliable partner for global manufacturers. By selecting a trusted supplier like Mingyuda, you gain more than just parts—you gain confidence, reliability, and long-term value for your manufacturing needs.

.webp)