MYD Circular Connectors

1. Military-Grade Waterproof Connector (IP68/IP69K)

Applications: Naval systems, field military equipment, subsea exploration devices

This connector features triple-sealing technology, maintaining perfect waterproof performance even at depths of 60 meters. Its military-spec gold-plated contacts resist saltwater corrosion, and its vibration resistance, tested under MIL-STD-810G, ensures contact resistance variation remains below 2% under extreme mechanical shock. The quick-lock mechanism enables fast deployment in critical missions.

2. High-Temperature Resistant Connector (up to 200°C)

Applications: Aerospace engines, industrial furnaces, automotive exhaust monitoring

Constructed with heat-resistant thermoplastics and ceramic insulation, this connector maintains stable signal transmission in environments up to 200°C. Its oxidation-resistant alloy contacts ensure long-term reliability in thermal cycling conditions.

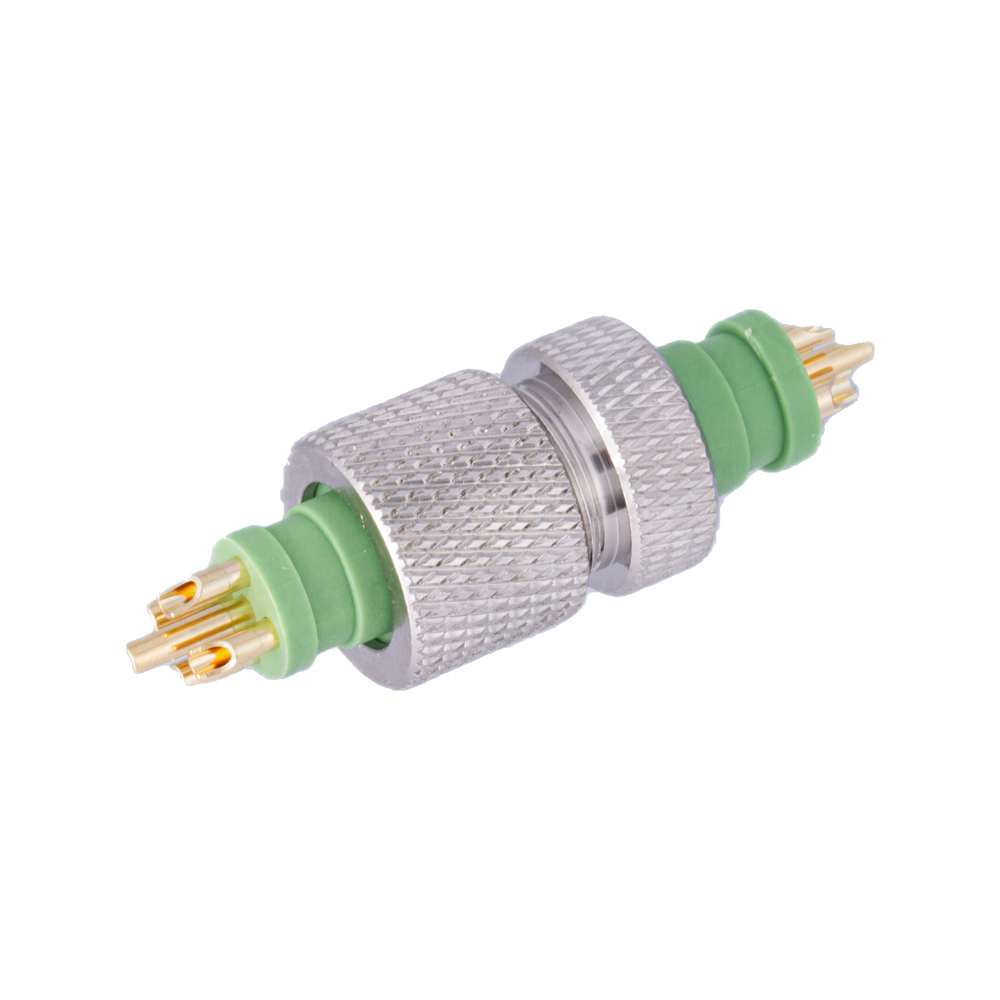

3. EMI/RFI Shielded Connector

Applications: Medical imaging, avionics, industrial automation

With 360° electromagnetic shielding effectiveness exceeding 90 dB, this connector prevents signal interference in sensitive electronic environments. Its conductive gasket design ensures consistent shielding even after repeated mating cycles.

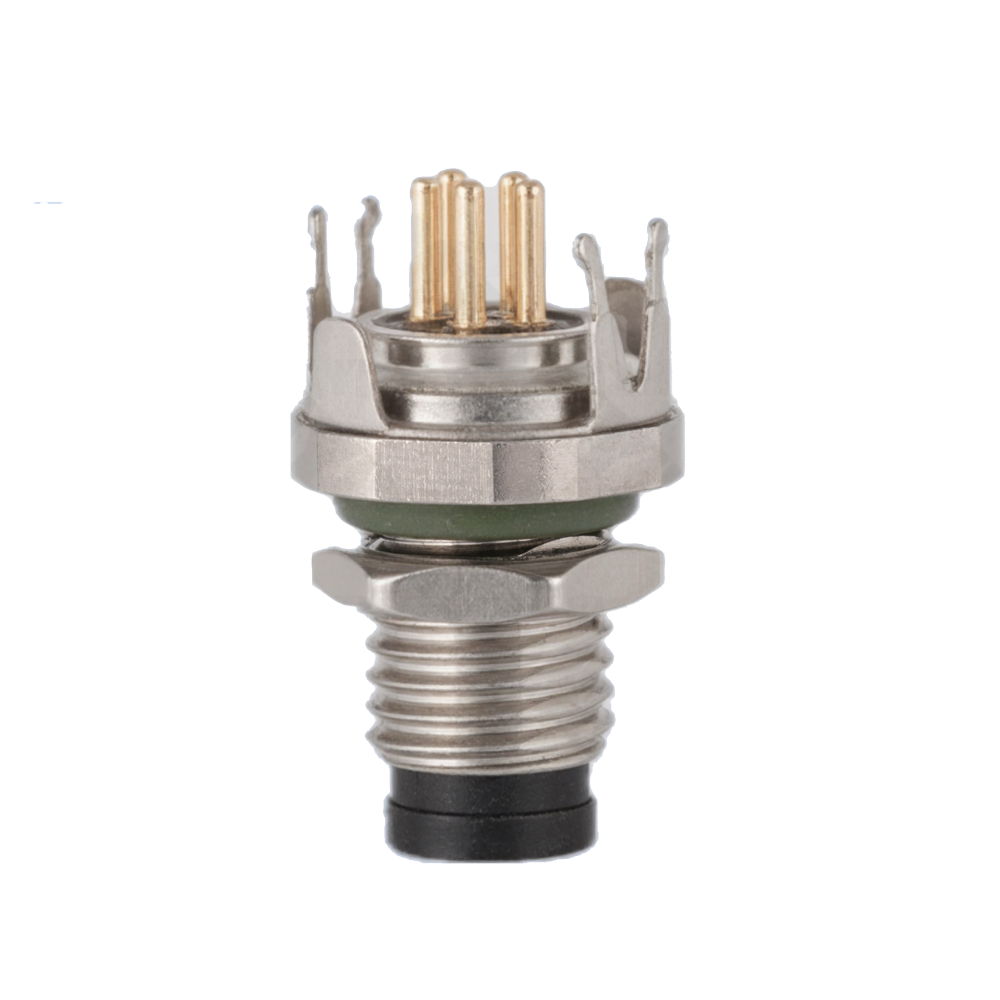

4. Miniature Circular Connector (12mm diameter)

Applications: Wearable devices, drones, robotics

Despite its compact size, this connector supports high-density configurations with up to 12 contacts. Its lightweight aluminum alloy housing provides strength without adding bulk, making it ideal for space-constrained applications.

5. High-Speed Data Connector (10Gbps+)

Applications: Industrial IoT, 5G infrastructure, autonomous vehicles

Featuring impedance-matched contacts and twisted-pair configurations, this circular connector minimizes signal loss at high frequencies. Its backshell design reduces crosstalk, ensuring reliable data transmission in electrically noisy environments.

6. Explosion-Proof Connector (ATEX/IECEx certified)

Applications: Oil & gas, chemical plants, mining

The flame-arresting design prevents ignition of hazardous atmospheres. Spark-resistant materials and hermetically sealed chambers meet Zone 1/Division 1 safety requirements for explosive environments.

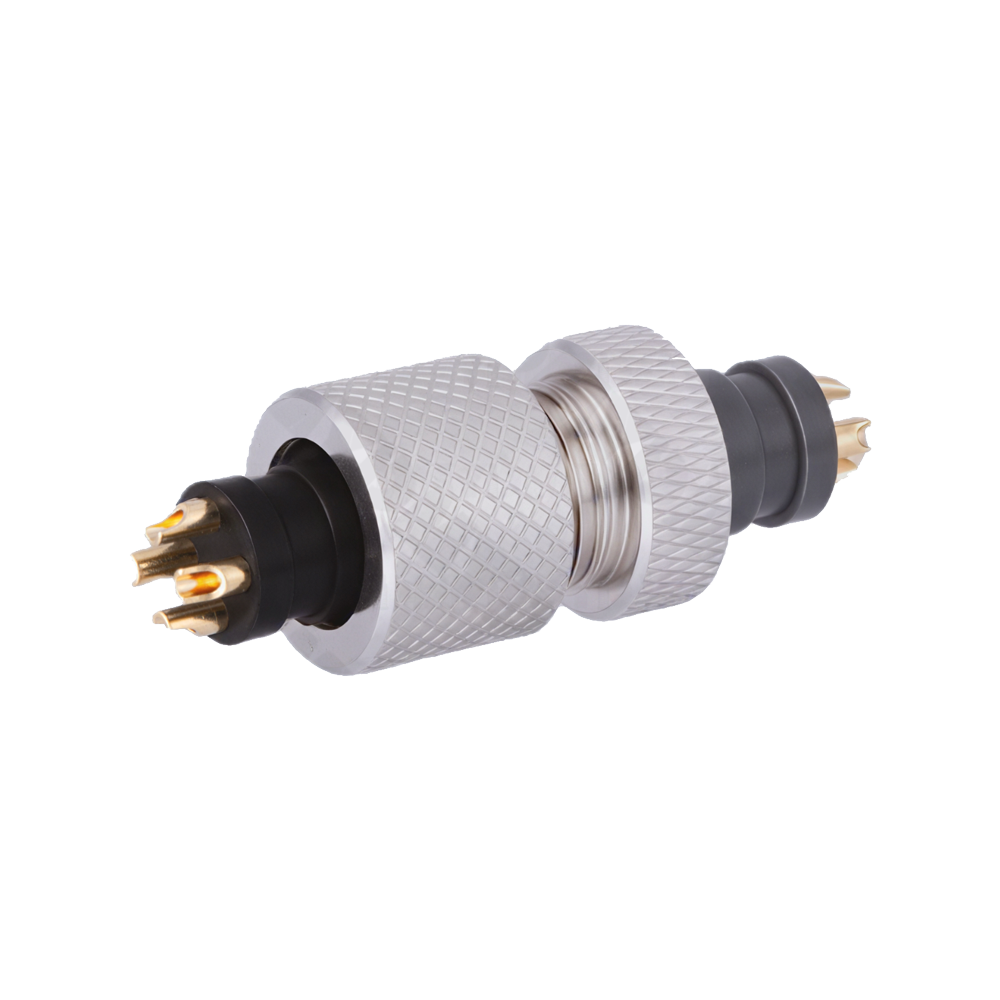

7. Heavy-Duty Industrial Connector

Applications: Construction machinery, agricultural equipment, railway systems

With a stainless steel shell and vibration-resistant contact system, this connector withstands 100G mechanical shock. Its self-cleaning contacts maintain connectivity in dusty or muddy conditions common in off-road applications.

8. Fiber-Optic Hybrid Connector

Applications: Telecom base stations, medical lasers, defense comms

Combining electrical power and optical data channels in one ruggedized housing, this hybrid solution eliminates separate cabling needs. The precision-aligned ferrule design maintains <0.5dB insertion loss even after 5,000 mating cycles.

9. Quick-Disconnect Medical Connector

Applications: Patient monitoring, surgical robotics, diagnostic equipment

Featuring a color-coded, tool-free coupling system for error-proof connections in emergency situations. The biocompatible housing resists hospital-grade disinfectants without degradation.

10. Submersible Pressure-Resistant Connector

Applications: Oceanographic sensors, ROVs, offshore energy

Tested to 5,000 psi hydrostatic pressure, this deep-sea connector utilizes pressure-balanced oil-filled chambers to prevent housing collapse. The titanium construction provides exceptional strength-to-weight ratio for subsea deployments.

Key Selection Criteria for Buyers

When promoting these connectors, emphasize:

Environmental ratings (IP, MIL-SPEC, ATEX)

Material science (corrosion-resistant alloys, advanced polymers)

Performance data (insertion loss, mating cycles, temperature range)

Industry certifications (UL, IEC, NEBS)

Application-specific designs (strain relief, cable glands, backshell options)